Although there is some truth in this statement the basic principle of washing machines – a rotating drum – has not changed since the 18th century. However, washing machines have evolved tremendously in these centuries from a manually operated wooden barrel to a technological marvel commonly found in most households, thanks to modern microelectronics.

The introduction of microelectronics in washing machines did not only increase ease of use but also helps to be more sustainable and save resources. Especially in the EU where resourcefulness is key, an intelligent motor management can help achieving energy and resource consumption goals.

A crucial part of every washing machine is its motor and its controller. A bad motor controller IC can cause all sorts of unwanted issues such as excessive heat and power consumption, noise (acoustic & EMI), and, in worst case, damage surrounding components of the system.

Generally, a motor controller needs to be able to #1 reach high torque from close to 0 RPM. Depending on the machine’s design a #2 suitable RPM range must be achievable: for belt driven washing machine generally higher speeds are needed (200 – 18000 RPM) while direct drive machines operate at 20 – 1600 RPM. For mass production, the controller needs to #3 compatible with multiple motors (of a product series without the need for difficult customizations). Further, the controller must be able to #4 detect eccentricity and be able to correct it, while always #5 controlling for overshooting voltage.

Fortior’s solution:

- Patented VAO estimator algorithm enabling the motor to reach 90% of its maximum torque rating at just 2Hz.

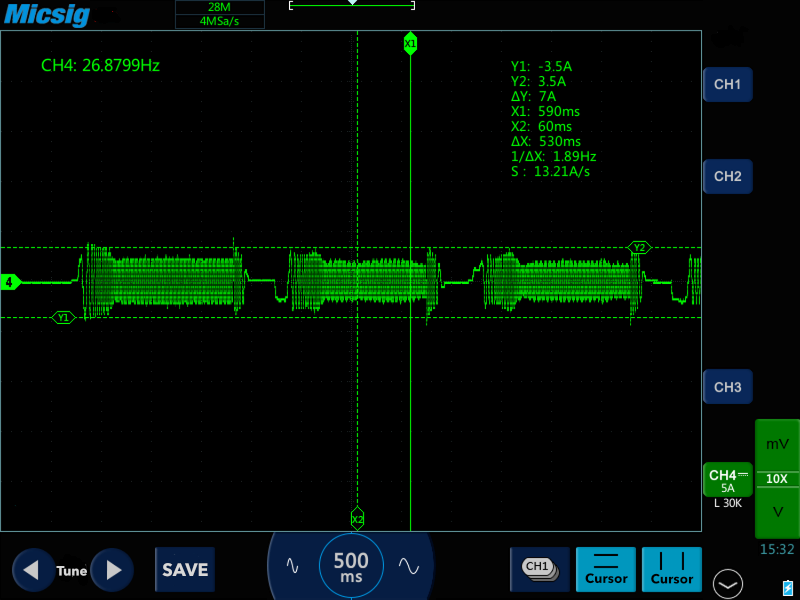

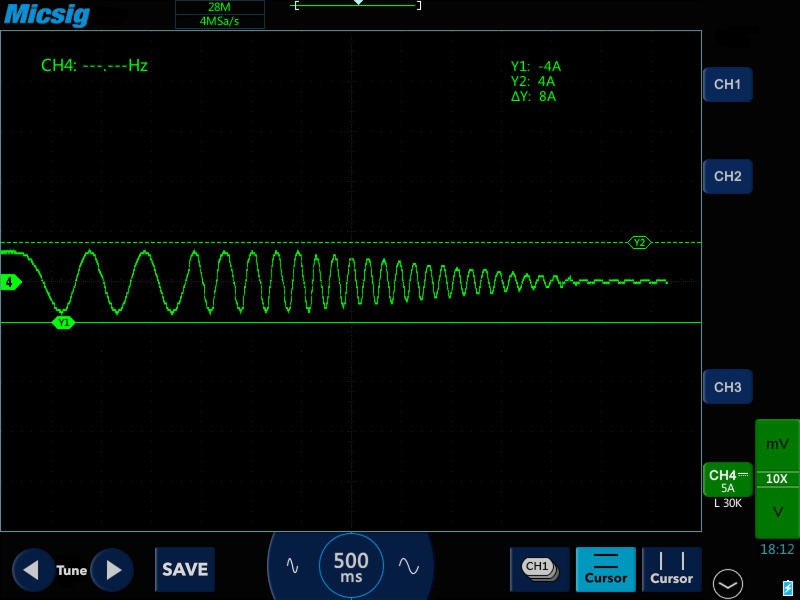

In the washing stage a speed of 750 RPM can be reached within 500ms (even when fully loaded!) and only 200ms from max RPMto 0 (top loaded pulsator washing machine). In the dehydration stage, the estimator works reliably even at lower speeds (~30 RPM) ensuring smooth operation and less vibrations.

- Different programs for different motors can be selected simply by changing resistances

- Patented voltage protection algorithm limits voltage overshoot and protects components such as the motor

- Highly effective flux-weakening achieves weaker flux for enhanced RPM range and a linear speed regulation curve

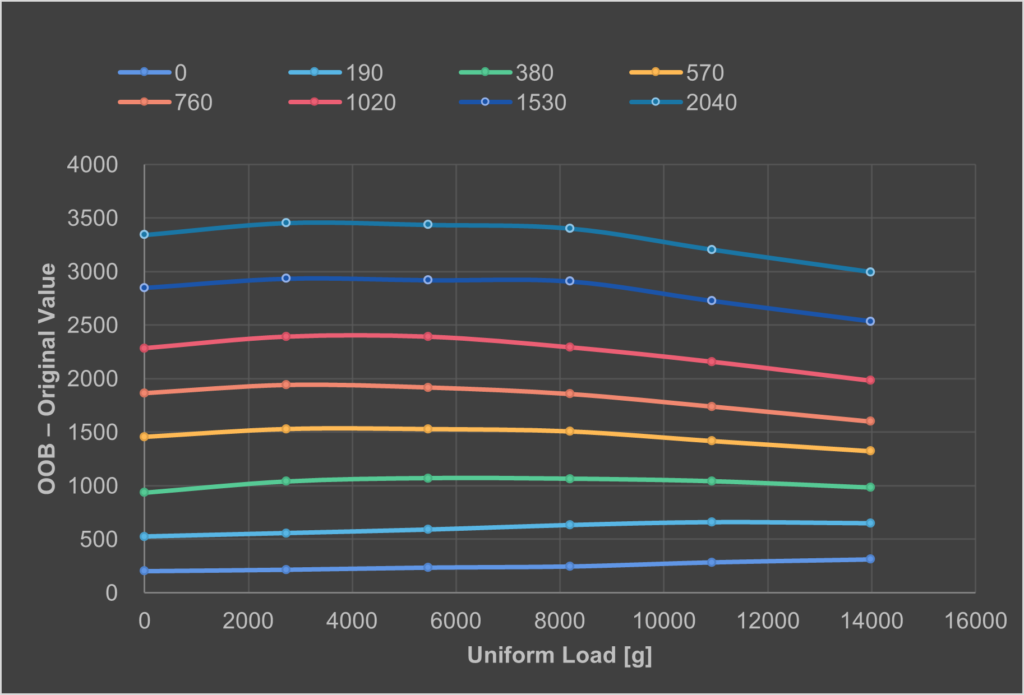

- Patented multi-dimensional eccentricity protection algorithm (detection accuracy 20g, weighing accuracy 200g)

Fortior’s algorithm uses a multi-dimensional imbalance calculation which effectively neutralizes the effect of the eccentricity at various loads of a drum washing machine keeping. (Test conditions: 2kg, 4kg, 8kg, 10kg, 12kg, 14kg load with corresponding eccentricities of 190g, 380g, 570g, 760g, 1020g, 1530g, 2040g)

If your application does need an innovative & cost-effective motor controller, give us a call or contact us directly & let’s discuss how ViMOS Technologies can bring YOUR application to life with Fortior’s motor control ICs.